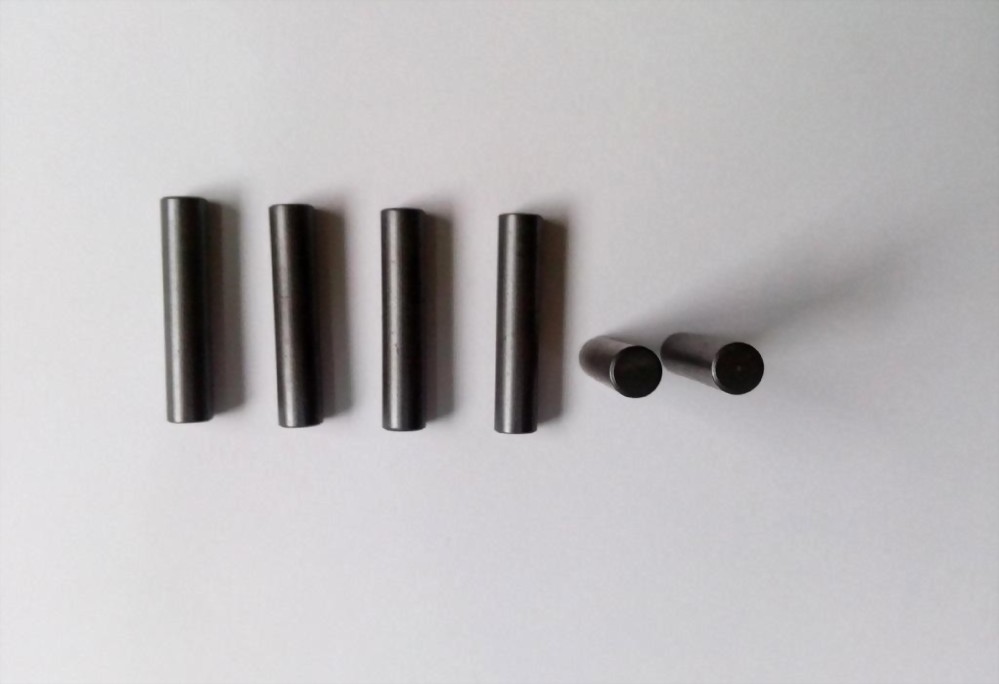

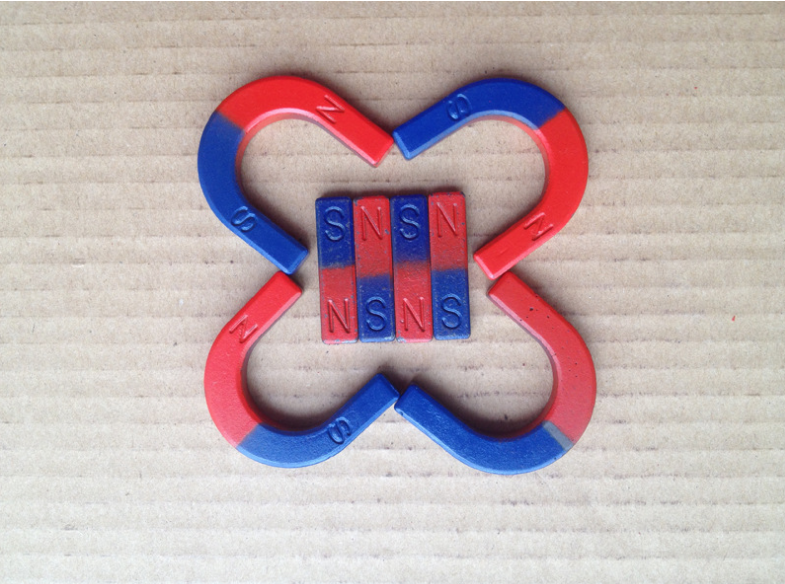

Ferrite Magnet

There are barium ferrite (BaO·6Fe2O3) and strontium ferrite (SrO·6Fe2O3). It has high resistivity and belongs to semiconductor type, so the eddy current loss is small and the coercive force is large. It can be effectively used in the magnetic circuit with large air gap, especially suitable for permanent magnets of small generators and motors.

It does not contain precious metal nickel, cobalt, etc., has rich sources of raw materials, uncomplicated process, and low cost, and can replace AlNiCo permanent magnets. Its maximum magnetic energy product (B+H)m is lower, so in the case of equal magnetic energy, it is larger than metal magnets.

Its temperature stability is poor, its texture is brittle and fragile, and it is not resistant to shock and vibration. It is not suitable for measuring instruments and magnetic devices with precision requirements. Permanent ferrite products are mainly anisotropic series. They can be used to make permanent magnet ignition motors, permanent magnet motors, permanent magnet separators, permanent magnet suspension heads, magnetic thrust bearings, magnetic separators, speakers, microwave devices, magnetic therapy tablets, hearing aids, etc.

Permanent magnet ferrite is made of SrO or BaO and ferric oxide through ceramic technology. Because of its cheap raw material price and relatively simple production process, its finished product price is relatively lower than other magnets. The main raw material of ferrite magnet is oxide, so it will not be corroded by the environment or chemical substances (except strong acid), so the surface does not need electroplating treatment. Mainly used in handicrafts, adsorption parts, toys, motors, speakers, etc.physical properties (Production Process)

01、Mixing

02、Powder production

03、Fine Milling

04、Pressing

05、Sintering

06、Testing

07、Cutting and Grinding

08、Cleaning

09、Inspection

10、Packing

11 、Delivery

12、After-sae service

performance table

Ferrite Segment Standard of Young Magnet

|

比重 |

性能 |

剩磁 |

矯頑力 |

內稟矯頑力 |

最大磁能積 |

燒結密度 |

||||

|

Br |

BHc |

IHc |

(BH)max |

|||||||

|

mT |

Gs |

Oe |

KA/m |

Oe |

KA/m |

MGOe |

KJ/m³ |

g/cm³ |

||

|

20% |

YC29 |

370 |

3700 |

3390 |

270 |

4000 |

318 |

3.28 |

26.1 |

4.8 |

|

YC29H |

360 |

3600 |

3400 |

271 |

4800 |

382 |

3.01 |

24 |

4.8 |

|

|

YC30 |

390 |

3900 |

2900 |

231 |

2950 |

235 |

3.6 |

28.7 |

4.8 |

|

|

YC30B |

410 |

4100 |

2510 |

200 |

2600 |

207 |

3.9 |

31.2 |

4.8 |

|

|

YC31 |

410 |

4100 |

231 |

2900 |

2950 |

235 |

4.09 |

32.6 |

4.9 |

|

|

YC32 |

380 |

3800 |

3500 |

279 |

4000 |

318 |

3.29 |

26.2 |

4.8 |

|

|

YC33 |

400 |

4000 |

3350 |

267 |

3500 |

279 |

3.8 |

30.3 |

4.9 |

|

|

YC34 |

420 |

4200 |

2800 |

223 |

2850 |

227 |

4.2 |

33.6 |

4.9 |

|

|

80% |

YC35 |

400 |

4000 |

3640 |

290 |

4000 |

318 |

3.9 |

31.2 |

4.9 |

|

YC35B |

420 |

4200 |

3200 |

255 |

3300 |

263 |

4.3 |

34.4 |

4.9 |

|

|

YC36 |

410 |

4100 |

3770 |

300 |

4400 |

350 |

4.1 |

32.8 |

4.9 |

|

|

YC36B |

425 |

4250 |

3640 |

290 |

4000 |

318 |

4.4 |

35.2 |

4.9 |

|

|

YC36H |

390 |

3900 |

3790 |

302 |

4800 |

382 |

3.6 |

28.9 |

4.9 |

|

|

YC37H |

420 |

4200 |

4000 |

318 |

4800 |

382 |

4.3 |

34.4 |

4.9 |

|

|

YC37B |

440 |

4400 |

4000 |

318 |

4400 |

350 |

4.6 |

36.7 |

4.9 |

|

(Europe Standard)

(The standard from International Electronics Committee (IEC404-8-1)

|

Grade |

Allowed Value (min/typical) |

|||||||

|

Br |

Hcb(BHC) |

Hcj(IHC) |

(BH)max |

|||||

|

mT |

KG |

KA/m |

KOe |

KA/m |

KOe |

Kj/m³ |

MGOe |

|

|

HF8/24 |

200-220 |

2.00-2.20 |

125-140 |

1.57-1.76 |

220-230 |

2.76-2.89 |

6.5-6.8 |

0.8-1.1 |

|

HF20/19 |

320-333 |

3.20-3.33 |

170-190 |

2.14-2.39 |

190-200 |

2.39-2.51 |

20.0-21.0 |

2.5-2.7 |

|

HF20/28 |

310-325 |

3.10-3.25 |

220-230 |

2.76-2.89 |

280-290 |

3.52-3.64 |

20.0-21.0 |

2.5-2.7 |

|

HF22/30 |

350-365 |

3.50-3.65 |

255-265 |

3.20-3.33 |

290-300 |

3.64-3.77 |

22.0-23.5 |

2.8-3.0 |

|

HF24/16 |

350-365 |

3.50-3.65 |

155-175 |

1.95-2.20 |

160-180 |

2.01-2.26 |

24.0-25.5 |

3.0-3.2 |

|

HF24/23 |

350-365 |

3.50-3.65 |

220-230 |

2.76-2.89 |

230-240 |

2.89-3.01 |

24.0-25.5 |

3.0-3.2 |

|

HF24/35 |

360-370 |

3.60-3.70 |

260-270 |

3.27-3.39 |

350-360 |

4.40-4.52 |

24.0-25.5 |

3.0-3.2 |

|

HF26/16 |

370-380 |

3.70-3.80 |

155-175 |

1.95-2.20 |

160-180 |

2.01-2.26 |

26.0-27.0 |

3.2-3.4 |

|

HF26/18 |

370-380 |

3.70-3.80 |

175-190 |

2.20-2.39 |

180-190 |

2.26-2.39 |

26.0-27.0 |

3.3-3.4 |

|

HF26/24 |

370-380 |

3.70-3.80 |

230-240 |

2.89-3.01 |

240-250 |

3.01-3.14 |

26.0-27.0 |

3.3-3.4 |

|

HF26/26 |

370-380 |

3.70-3.80 |

230-240 |

2.89-3.01 |

260-270 |

3.27-3.39 |

26.0-27.0 |

3.3-3.4 |

|

HF26/30 |

385-395 |

3.85-3.95 |

260-270 |

3.27-3.39 |

300-310 |

3.77-3.89 |

26.0-27.0 |

3.3-3.4 |

|

HF28/20 |

390-400 |

3.90-4.00 |

195-200 |

2.45-2.52 |

200-210 |

2.51-2.64 |

28.5-29.0 |

3.6-3.7 |

|

HF28/26 |

385-395 |

3.85-3.95 |

250-265 |

3.14-3.33 |

260-275 |

3.27-3.45 |

28.0-30.0 |

3.5-3.8 |

|

HF28/28 |

385-395 |

3.85-3.95 |

260-270 |

3.27-3.39 |

280-290 |

3.50-3.60 |

28.0-30.0 |

3.5-3.8 |

|

HF30/26 |

395-405 |

3.95-4.05 |

250-260 |

3.14-3.33 |

260-270 |

3.27-3.39 |

30.0-31.5 |

3.8-3.9 |

|

HF32/17 |

410-420 |

4.10-4.20 |

160-180 |

2.01-2.26 |

165-175 |

2.07-2.20 |

32.0-33.0 |

4.0-4.1 |

|

HF32/22 |

410-420 |

4.10-4.20 |

215-225 |

2.70-2.83 |

220-230 |

2.76-2.89 |

32.0-33.0 |

4.0-4.1 |

|

HF32/25 |

410-420 |

4.10-4.20 |

240-250 |

3.01-3.14 |

250-260 |

3.14-3.27 |

32.0-33.0 |

4.0-4.1 |

(Chinese SJ/T10410-2000 permanent ferrite magnet standard )

|

Material |

Br |

HcB |

HcJ |

(BH)max |

||||

|

mT |

KGs |

KA/m |

KOe |

KA/m |

KOe |

Kj/m³ |

MGOe |

|

|

Y10T |

200-235 |

2.0-2.35 |

125-160 |

1.57-2.01 |

210-280 |

2.64-3.52 |

6.5-9.5 |

0.8-1.2 |

|

Y20 |

320-380 |

3.2-3.8 |

135-190 |

1.70-2.38 |

140-195 |

1.76-2.45 |

18.0-22.0 |

2.3-2.8 |

|

Y22H |

310-360 |

3.1-2.6 |

220-250 |

2.77-3.14 |

280-320 |

3.52-4.02 |

20.0-24.0 |

2.5-3.0 |

|

Y25 |

360-380 |

3.6-3.8 |

135-170 |

1.70-2.14 |

140-200 |

1.76-2.51 |

22.5-28.0 |

2.8-3.5 |

|

Y26H |

360-390 |

3.6-3.9 |

220-250 |

2.77-3.14 |

225-255 |

2.83-3.21 |

23.0-28.0 |

2.9-3.5 |

|

Y27H |

370-400 |

2.7-4.0 |

205-250 |

2.58-3.14 |

210-255 |

2.64-3.21 |

25.0-29.0 |

3.1-3.7 |

|

Y30 |

370-400 |

3.7-4.0 |

175-210 |

2.20-2.64 |

180-220 |

2.26-2.77 |

26.0-30.0 |

3.3-3.8 |

|

Y30BH |

380-390 |

3.8-3.9 |

223-235 |

2.80-2.95 |

231-245 |

2.90-3.08 |

27.0-30.0 |

3.4-3.7 |

|

Y30H-1 |

380-400 |

3.8-4.0 |

230-275 |

2.89-3.46 |

235-290 |

2.95-3.65 |

27.0-32.5 |

3.4-4.0 |

|

Y30H-2 |

395-415 |

3.95-4.15 |

275-300 |

3.46-3.77 |

310-335 |

3.90-4.21 |

28.5-32.5 |

3.5-4.0 |

|

Y32 |

400-410 |

4.0-4.2 |

160-190 |

2.01-2.38 |

165-195 |

2.07-2.45 |

30.0-33.5 |

3.8-4.2 |

|

Y35 |

410-430 |

4.1-4.3 |

208-218 |

2.60-2.75 |

210-230 |

2.60-2.81 |

30.4-32.0 |

3.8-4.0 |

|

Y36 |

430-450 |

4.30-4.50 |

247-271 |

3.10-3.40 |

250-274 |

3.14-3.44 |

35.1-38.3 |

4 .4-4.8 |

|

Y38 |

440-460 |

4.40-4.60 |

285-305 |

3.58-3.83 |

294-310 |

3.69-3.89 |

36.6-40.6 |

4 .6-5.1 |

|

Y40 |

440-460 |

4.40-4.60 |

330-354 |

4.15-4.45 |

340-360 |

4.27-4.52 |

37.6-41.8 |

4 .7-5.2 |

(USA Standard)

|

Grade |

Br |

HcB |

HcJ |

(BH)max |

||||

|

mT |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/m³ |

MGOe |

|

|

C1 |

230 |

2.3 |

148 |

1.86 |

258 |

3.5 |

8.36 |

1.05 |

|

C5 |

380 |

3.8 |

191 |

2.4 |

199 |

2.5 |

27 |

3.4 |

|

C7 |

340 |

3.4 |

258 |

3.23 |

318 |

4 |

21.9 |

2.75 |

|

C8(C8A) |

385 |

3.85 |

235 |

2.95 |

242 |

3.05 |

27.8 |

3.5 |

|

C9 |

380 |

3.8 |

280 |

3.516 |

320 |

4.01 |

26.4 |

3.32 |

|

C10 |

400 |

4 |

288 |

3.617 |

280 |

3.51 |

30.4 |

3.82 |

|

C11 |

430 |

4.3 |

200 |

2.512 |

204 |

2.56 |

34.4 |

4.32 |