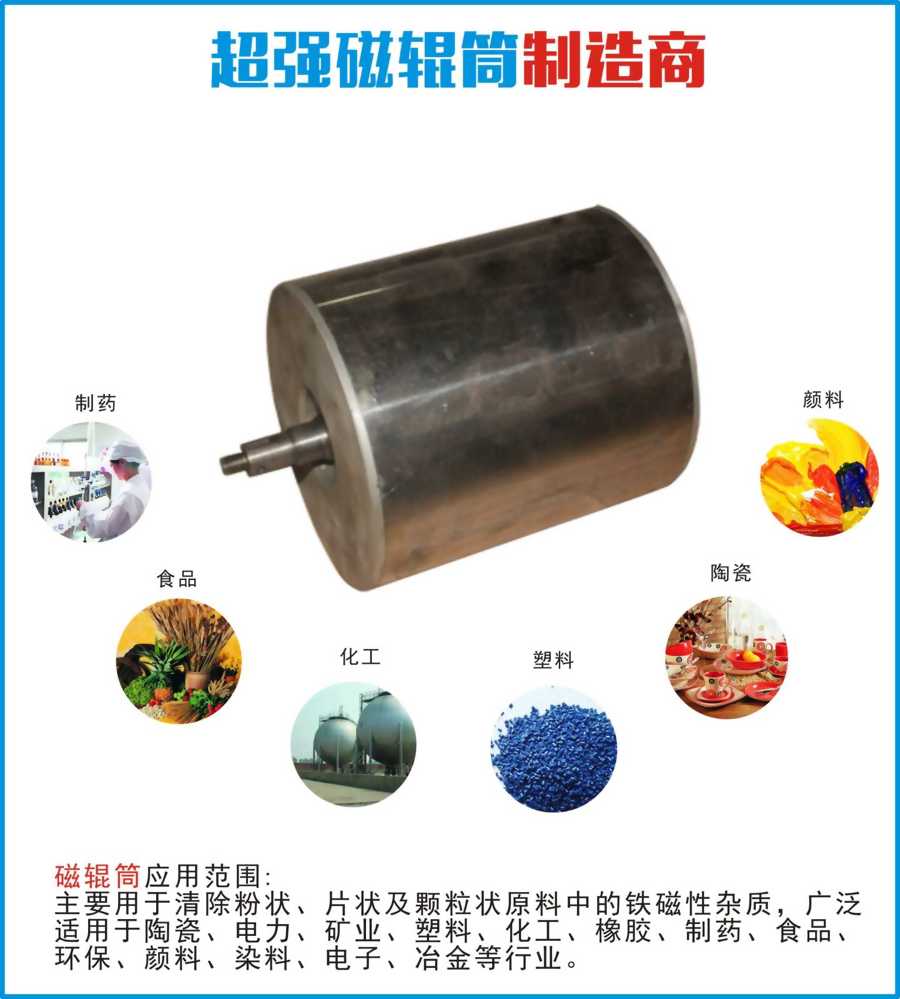

Magnet Roller

Features:

1.Different magnetic action range plate with strong magnetic strength are available .

2.Easy cleaning and assembling.

3.Surface material is 304 or 316L stainless steel ,no pollution to materials.

4.Dimension and extra parts, such as hinge, handle, or mounting hole can be custom made.

Schematic way of magnetic drum:

(Surface material: stainless steel SUS304)

|

Magnetic Roller |

Surface Magnetism(GS) |

diameter(mm) |

Magnetic part(mm) |

Total length of scrolling axis(mm) |

|

MTB |

15000 |

Φ150 |

500 |

810 |

Magnetic drum specifications and delivery instructions:

There are many specifications of the magnetic drum, and the specific size can be designed and manufactured according to the actual situation of the customer. The surface magnetism is up to 15000~16000GS. Orders within 3 pieces will be delivered within 2 weeks after signing back.

|

Magnetic drum diameterΦ |

Magnetic drum length:A |

Magnetic drum shaft size:B |

Magnetic strength |

|||||

|

1000 GS |

3000 GS |

4500 GS |

10000 GS |

13000 GS |

15000 GS |

|||

|

Φ60(2.36”) |

According to the actual requirements of customers |

According to the actual requirements of customers |

√ |

√ |

√ |

√ |

√ |

— |

|

Φ110(4.33”) |

√ |

√ |

√ |

√ |

√ |

— |

||

|

Φ114(4.49”) |

√ |

√ |

√ |

√ |

— |

— |

||

|

Φ150(5.90”) |

√ |

√ |

√ |

√ |

√ |

√ |

||

|

Φ156(6.14”) |

√ |

√ |

— |

— |

— |

— |

||

|

Φ200(7.87”) |

√ |

√ |

√ |

√ |

— |

— |

||

|

Φ300(11.81”) |

√ |

√ |

√ |

√ |

— |

— |

||

Application:

Mgnetic plate can remove tramp iron such as Bolts, Nuts, Bits of Wire, Nails and other casual impurities from free flowing materials, like gravel, corn, sugar, plastic, flour and other granular materials in the conveying course.

Working Principle:

The magnetic roller is constituted of high quality stainless steel tube and high B value rare earth NdFeB alloy.It could be hung on the conveyor belt, trough, pipeline, feed plate, above or the end of the conveyor belt, so to constitute a magnetic filter. When the raw material pass through, the iron material and ferromagnetic impurities will be firmly attracted on the surface of the magnetic plate, to ensure the safety of products and equipments in good condition .