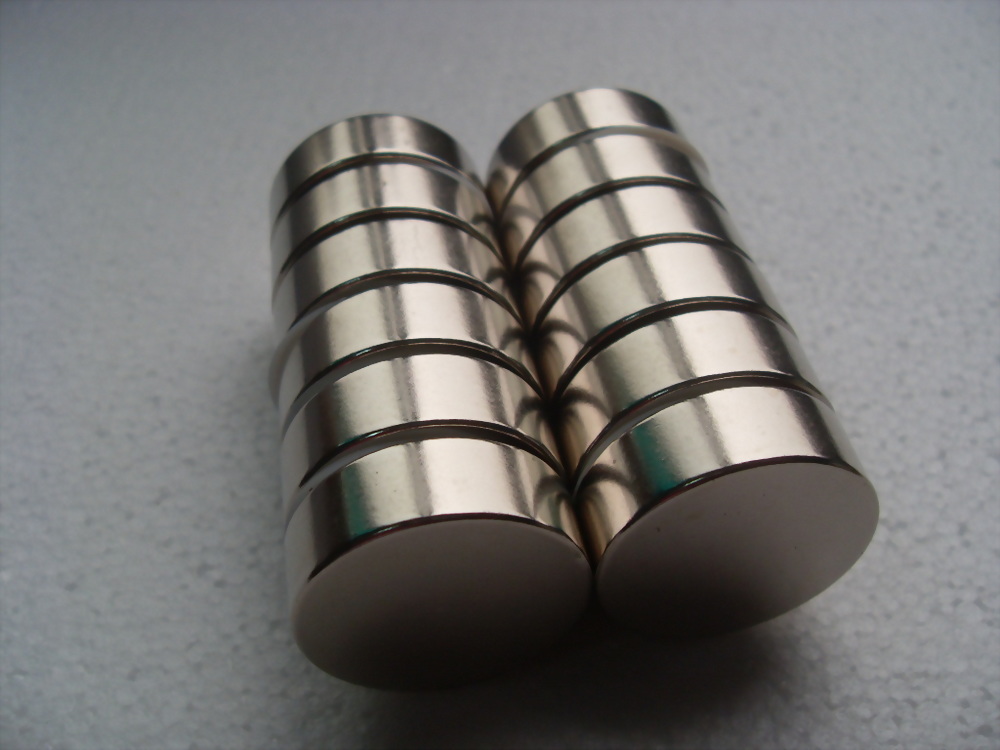

NdFeB

Neodymium magnet, also known as NdFeB magnet or Neo magnet, is one of the highest property and strongest permanent magnet by now, are made through powder metallurgy manufacturing techniques. They are mainly composed of neodymium(32%), iron(64%), boron(1%), and a few quantity rare earth material, such as Dy, Tb, Co, Nb, Ga, Al, Cu,etc.

Neodymium magnet is regarded as “Magnet King” due to its recorded high remanence, coercive force and maximum energy product. Initially, NdFeB magnets were primarily used for making VCM’s (voice coil motors) in hard disk drives. Now they are widely used in many fields, such as automotive industry, communication tools, engineering equipment, medical equipment, audio apparatus and household etc. And with Neodymium magnet rapid development, many high-tech products were developed. With advanced scientific research and production equipments, we can supply various dimension neodymium magnets with high property and enduring high temperature.

Besides normal N35 ~ N52, temperature stability magnets could reach 50M, 48H, 45SH, 42UH, 40EH, 33AH. Also, to bear special working environment, we supply low weight loss magnet.

Features of Neodymium Magnet:

1. Super strong Br Resident induction.

2. Excellent demagnetization resistance capability.

3. Reasonable Price relative to its high magnetic properties.

4. Coating is necessary for NdFeB.

Production Process

|

類別 |

性能 |

剩磁 |

矯頑力 |

內稟矯頑力 |

最大磁能積 |

工作溫度 |

||||

|

Br |

BHc |

IHc |

(BH)max |

|||||||

|

mT |

KG |

KOe |

KA/m |

KOe |

KA/m |

MGOe |

KJ/m³ |

℃ |

||

|

N |

N35 |

1170-1220 |

11.7-12.2 |

≧10.9 |

≧868 |

≧12 |

≧955 |

33-36 |

263-287 |

≤80℃ |

|

N38 |

1220-1250 |

12.2-12.5 |

≧11.3 |

≧899 |

≧12 |

≧955 |

36-39 |

287-310 |

≤80℃ |

|

|

N40 |

1250-1280 |

12.5-12.8 |

≧11.4 |

≧907 |

≧12 |

≧955 |

38-41 |

302-326 |

≤80℃ |

|

|

N42 |

1280-1320 |

12.8-13.2 |

≧11.5 |

≧915 |

≧12 |

≧955 |

40-43 |

318-342 |

≤80℃ |

|

|

N45 |

1320-1380 |

13.2-13.8 |

≧11.6 |

≧923 |

≧12 |

≧955 |

43-46 |

342-366 |

≤80℃ |

|

|

N48 |

1380-1420 |

13.8-14.2 |

≧11.6 |

≧923 |

≧12 |

≧955 |

46-49 |

366-390 |

≤80℃ |

|

|

N50 |

1400-1450 |

14.0-14.5 |

≧10.0 |

≧796 |

≧11 |

≧876 |

48-51 |

382-406 |

≤80℃ |

|

|

N52 |

1430-1480 |

14.3-14.8 |

≧10.0 |

≧796 |

≧11 |

≧876 |

50-53 |

398-422 |

≤80℃ |

|

|

M |

N35M |

1170-1220 |

11.7-12.2 |

≧10.9 |

≧868 |

≧14 |

≧1114 |

33-36 |

263-287 |

≤100℃ |

|

N38M |

1220-1250 |

12.2-12.5 |

≧11.3 |

≧899 |

≧14 |

≧1114 |

36-39 |

287-310 |

≤100℃ |

|

|

N40M |

1250-1280 |

12.5-12.8 |

≧11.6 |

≧923 |

≧14 |

≧1114 |

38-41 |

302-326 |

≤100℃ |

|

|

N42M |

1280-1320 |

12.8-13.2 |

≧12.0 |

≧955 |

≧14 |

≧1114 |

40-43 |

318-342 |

≤100℃ |

|

|

N45M |

1320-1380 |

13.2-13.8 |

≧12.5 |

≧955 |

≧14 |

≧1114 |

43-46 |

342-366 |

≤100℃ |

|

|

N48M |

1360-1430 |

13.6-14.3 |

≧12.9 |

≧1027 |

≧14 |

≧1114 |

46-49 |

366-390 |

≤100℃ |

|

|

N50M |

1400-1450 |

14.0-14.5 |

≧13.0 |

≧1033 |

≧14 |

≧1114 |

48-51 |

382-406 |

≤100℃ |

|

|

H |

N33H |

1130-1170 |

11.3-11.7 |

≧10.5 |

≧836 |

≧17 |

≧1353 |

31-34 |

247-271 |

≤120℃ |

|

N35H |

1170-1220 |

11.7-12.2 |

≧10.9 |

≧868 |

≧17 |

≧1353 |

33-36 |

263-287 |

≤120℃ |

|

|

N38H |

1120-1250 |

12.2-12.5 |

≧11.3 |

≧899 |

≧17 |

≧1353 |

36-39 |

287-310 |

≤120℃ |

|

|

N40H |

1250-1280 |

12.5-12.8 |

≧11.6 |

≧923 |

≧17 |

≧1353 |

38-41 |

302-326 |

≤120℃ |

|

|

N42H |

1280-1320 |

12.8-13.2 |

≧12.0 |

≧955 |

≧17 |

≧1353 |

40-43 |

318-342 |

≤120℃ |

|

|

N45H |

1300-1360 |

13.0-13.6 |

≧12.0 |

≧955 |

≧17 |

≧1353 |

43-46 |

342-366 |

≤120℃ |

|

|

N48H |

1370-1430 |

13.7-14.3 |

≧12.5 |

≧955 |

≧17 |

≧1353 |

46-49 |

366-390 |

≤120℃ |

|

|

SH |

N30SH |

1080-1130 |

10.8-11.3 |

≧10.1 |

≧804 |

≧20 |

≧1592 |

28-31 |

223-247 |

≤150℃ |

|

N33SH |

1130-1220 |

11.3-12.2 |

≧10.6 |

≧844 |

≧20 |

≧1592 |

31-34 |

247-271 |

≤150℃ |

|

|

N35SH |

1170-1220 |

11.7-12.2 |

≧11.0 |

≧876 |

≧20 |

≧1592 |

33-36 |

263-287 |

≤150℃ |

|

|

N38SH |

1220-1250 |

12.2-12.5 |

≧11.4 |

≧907 |

≧20 |

≧1592 |

36-39 |

287-310 |

≤150℃ |

|

|

N40SH |

1240-1280 |

12.4-12.8 |

≧11.8 |

≧939 |

≧20 |

≧1592 |

38-41 |

302-326 |

≤150℃ |

|

|

N42SH |

1280-1320 |

12.8-13.2 |

≧12.4 |

≧987 |

≧20 |

≧1592 |

40-43 |

318-342 |

≤150℃ |

|

|

N45SH |

1320-1380 |

13.2-13.8 |

≧12.6 |

≧1003 |

≧20 |

≧1592 |

43-46 |

342-366 |

≤150℃ |

|

|

UH |

N30UH |

1080-1130 |

10.8-11.3 |

≧10.2 |

≧812 |

≧25 |

≧1990 |

28-31 |

223-247 |

≤180℃ |

|

N33UH |

1130-1170 |

11.3-11.7 |

≧10.7 |

≧852 |

≧25 |

≧1990 |

31-34 |

247-271 |

≤180℃ |

|

|

N35UH |

1180-1220 |

11.8-12.2 |

≧10.8 |

≧860 |

≧25 |

≧1990 |

33-36 |

263-287 |

≤180℃ |

|

|

N38UH |

1220-1250 |

12.2-12.5 |

≧11.3 |

≧899 |

≧25 |

≧1990 |

36-39 |

287-310 |

≤180℃ |

|

|

N40UH |

1250-1280 |

12.5-12.8 |

≧11.3 |

≧899 |

≧25 |

≧1990 |

38-41 |

302-326 |

≤180℃ |

|

| N42UH | 1280-1320 | 12.8-13.2 | ≥ 12.4 | ≧899 | ≥ 25 | ≧1990 | 40-43 | 326-350 | ≤180℃ | |

|

EH |

N30EH |

1080-1130 |

10.8-11.3 |

≧10.2 |

≧812 |

≧30 |

≧2388 |

28-31 |

223-247 |

≤200℃ |

|

N33EH |

1130-1170 |

11.3-11.7 |

≧10.5 |

≧832 |

≧30 |

≧2388 |

31-34 |

247-271 |

≤200℃ |

|

|

N35EH |

1170-1220 |

11.7-12.2 |

≧11.0 |

≧876 |

≧30 |

≧2388 |

33-36 |

263-287 |

≤200℃ |

|

|

N38EH |

1220-1260 |

12.2-12.6 |

≧11.3 |

≧899 |

≧30 |

≧2388 |

36-39 |

287-310 |

≤200℃ |

|

|

N40EH |

1260-1300 |

12.6-13.0 |

≧11.8 |

≧939 |

≧30 |

≧2388 |

38-43 |

302-342 |

≤200℃ |

|

|

AH |

N30AH |

1080-1130 |

10.8-11.3 |

≧10.2 |

≧812 |

≧35 |

≧2785 |

28-31 |

223-247 |

≤240℃ |

|

N33AH |

1130-1170 |

11.3-11.7 |

≧10.2 |

≧812 |

≧35 |

≧2785 |

31-34 |

247-271 |

≤240℃ |

|

Surface Treatment of NdFeB magnet

NdFeB magnets are susceptible to corrosion, so it is necessary to give surface treatment Currently, the surface treatments mainly includes chemical plating, conversion coating and coating. In most cases, NdFeB magnet surface are treated with NiCuNi (Nickel-Copper-Nickel) plating, Zinc plating and Epoxy coating. For special requirements, passivation and phosphatization are also adopted.

釹鐵硼磁鐵電鍍

釹鐵硼作為稀土永磁材料的一種具有極高的磁能積和矯頑力,同時高能量密度的優點使釹鐵硼永磁材料在現代工業和電子技術中獲得了廣泛應用,從而使儀器儀錶、電聲電機、磁選磁化等設備的小型化、輕量化、薄型化成為可能。釹鐵硼的優點是性價比高,具良好的機械特性;釹鐵硼中含有大量的稀土元素釹、鐵及硼,其特性硬而脆。同時,釹等稀土金屬非常活潑,使材料易於粉化腐蝕,必須通過採取表面處理方法或調整其化學成分使之得以改進,才能達到實際應用的要求。由於調整成分會改變其性能等,所以表面處理比較重要。

目前,釹鐵硼磁體的表面處理主要有電鍍(化學鍍)、轉化膜、塗層和氣相塗層等幾個方面。

一、電鍍

釹鐵硼電鍍最主要的是鍍鎳和鍍鋅。

鍍鎳根據鍍層結構不同,分為單鎳、雙鎳、鎳銅鎳等;根據外觀色澤不同,分暗鎳、半光亮鎳和光鎳。一般鍍鎳層為鎳銅鎳的亮鎳和半光亮鎳居多。鍍鎳的優點是鍍層較耐磨、耐環境性好等,比較差的是鎳層是鐵磁性物質,對磁性能有一定的影響,對薄小產品特別明顯,改進辦法是用部分銅層替代。化學鎳和電鍍鎳磷合金的鐵磁性較弱,但是退鍍比較麻煩,一般不作為主流鍍層供用。

化學鎳相對比電鍍鎳鎳層比較均勻,但是,目前尚不能在釹鐵硼的基體上直接施鍍,而且化學鎳使用大量的絡合劑、還原劑且鍍液壽命短、施鍍推動力低、能耗高,因此也不能作主流鍍層。

鍍鎳後產品,根據對鍍層的要求,還可以鍍金、銀、錫、代鉻、仿金、黑鎳等鍍層。

釹鐵硼鍍鋅一般採用採用氯化物鍍鋅,從國內產量上看,鍍鋅是最大的鍍種,特別是電動自行車磁鋼的電鍍更為突出。鍍層優點是便宜、方便、鋅層不是鐵磁性的。缺點是耐磨性、耐候性不如鍍鎳層 。鍍鋅後鍍層一般要進行鈍化處理,由於淘汰了六價鉻鈍化,目前常用的鈍化是三價鉻藍白鈍化和三價鉻彩色鈍化。當然,鍍鋅層鈍化也可以象五金件一樣更加豐富;但是,目前主流是三價鉻藍白鈍化。

電鍍層還有人使用過鋅鎳合金等,不過,到目前尚不能成為釹鐵硼電鍍的一種常規鍍種。

二、轉化膜

釹鐵硼的轉化膜主要有磷化和鈍化膜,由於轉化膜屬於工間保護膜等,用於長期,許多產品會有閃鏽等現象。

三、塗層

這裡所指的塗層是指用電泳、噴塗、刷塗和浸塗等工藝的鍍層,不包括氣相塗層。目前比較普遍的塗層有環氧漆塗層,其次分別是Everlube塗層、特氟龍塗層、無鉻達克羅塗層。

環氧塗層由於塗料品種的不同,耐鹽霧試驗、硬度、色澤等都有不同。Everlube塗層一般呈有金屬光澤的金黃色,是美國生產的一種固體潤滑膜改進過來的,塗層綜合性能非常優秀,已商品化。特氟龍塗層也已商品化。先進的無鉻達克羅也是一種有望替代電鍍的一種鍍層。

氣相塗層包括物理氣相沉積(PVD)法,物理氣相沉積又分蒸發鍍、濺射鍍、離子鍍三類,可形成Al、Zn、Cr等鍍層;化學氣相沉積CVD)則可形成Ti、Cr等的氮化物、碳化物鍍層;化學氣相沉積(CVD)聚合類塗層派瑞霖等。

|

鍍種(Surface) |

鍍層(Coating) |

厚度(Thickness) |

顏色(Color) |

鹽霧試驗SST(Hours) |

|

鎳(Nickel) |

鎳銅鎳(Ni+Cu+Ni) |

10~20μm |

銀白色(Bright Silver) |

24~72 |

|

特黑鎳(Black Nickel) |

鎳+銅+黑鎳(Ni+Cu+Ni) |

10~20μm |

亮黑色(Bright Black) |

48~96 |

|

環保鋅(Cr3+Zinc) |

藍白鋅(Zn) |

5~8μm |

藍白色(Blue white) |

16~48 |

|

彩鋅(CZn) |

5~8μm |

彩色(Color) |

36~72 |

|

|

錫(Sn) |

鎳銅鎳+錫(Ni+Cu+Ni+Sn) |

10~25μm |

銀色 (Silver) |

36~72 |

|

金(Au) |

鎳銅鎳+金(Ni+Cu+Ni+Au) |

10~20μm |

金色 (Gold) |

12 |

|

銀(Ag) |

鎳銅鎳+銀(Ni+Cu+Ni+Ag) |

10~20μm |

銀色 (Silver) |

12 |

|

環氧樹脂(Epoxy) |

環氧(Exopy) |

10~20μm |

黑色/灰色(Black/Grey) |

48 |

|

鎳+銅+環氧(Ni+Cu+Epoxy) |

15~30μm |

72~108 |

||

|

鋅+環氧(Zn+Epoxy) |

15~25μm |

72~108 |

||

|

鈍化(Passivation) |

//// |

1~3μm |

黑灰色(Dark Grey) |

臨時保護(temporary protection) |

|

磷化(Phosphate) |

//// |

1~3μm |

黑灰色(Dark Grey) |

臨時保護(temporary protection) |